[List of Manufacturing Process]

There are numerous manufacturing processes that use in different industries. Among them, the most frequently used processes for metals and thermoplastics will be briefly introduced here.

1. Casting

a) Die-casting

: It's a very similar process to injection moulding but uses molten metal. Low melting point alloys are the main materials for this type of process. Die casting facility requires high set-up cost, so it is the cost-effective solution for large volume productions.

b) Sand casting

: It is one of the traditional casting processes for metal casting. Due to the complexity of the process, it is more for small-batch or one-offs. Mould patterns are normally made in woods. This process is named as sand is packed between the mould patterns and mould boxes (flask) and after mould patterns are removed, tightly packed sand keeps the mould shape. This process tends to leave a rough surface finishing.

c) Investment casting

: Investment casting is named from a meaning of surrounding. A shell is created by surrounding a wax pattern. Molten metal is poured into the shell and after sufficient cooling, the shell is broken away and the cast part remains. Investment casting is valued for its beneficial features such as accuracy, repeatability and a broad range of metals and alloys that can be used.

2. Labeling and painting

a) Laser engraving

: Laser engraving is a process that engraves marks on an object surface using lasers. It is broadly used for various materials such as plastics, metals, woods, stones and glasses etc. Recently, 3D printers with a laser engraving head module get attention.

b) Chemical vapour deposition (CVD)

: Chemical vapour deposition is a method to deposit a solid material from a vapour involving chemical reactions. This process is often used in the semiconductor production line to produce thin films.

c) Thermal spraying

: It is a surface coating process using melted or heated materials. Thermal spraying can provide from around 20 microns to several mm. Coating quality is checked by porosity, hardness, roughness, bond strength and oxide content. This process is commonly used for a purpose, giving extra protection/resistance against the environment for products, for instance, medical, automotive, aerospace and nuclear applications.

3. Moulding

a) Injection moulding

: It's one of the most common manufacturing processes for thermoplastics due to its high-speed productivity. The process is similar to die casting but uses thermoplastics. Molten plastic is injected into a cavity mould and ejected after cooling.

4. Machining

a) Metal Lathe

: Using a metal bar to produce cylinder shape products such as screws, bolts, coaxial plugs, connectors, chamfers and adapters etc by rotating the metal. The process can be fully manual or with CNC. Due to its complex process, only small batch or one-off productions are ideal.

b) Milling

: Milling is the process that removing material from a workpiece by rotating cutting tools. Compared to the metal lathe, the milling machine uses multiple cutting tools in one or several axes. Both lathes and milling machines have the same purpose, removing materials from a workpiece, however, lathe machines rotate workpiece against a single-bladed cutting tool, while milling machines remove materials from a stationary workplace by rotating single or multi-bladed cutting tools.

5. Joining

a) Welding

: Welding is a fabrication process that fuses two materials by melting the parts with high heat. Mainly, a gas flame (chemical), an electric arc (electrical), a laser, an electron beam, friction and ultrasound are used as energy sources for welding. The process is hazardous due to its energy sources, therefore, highly skilled and trained welding professionals are required.

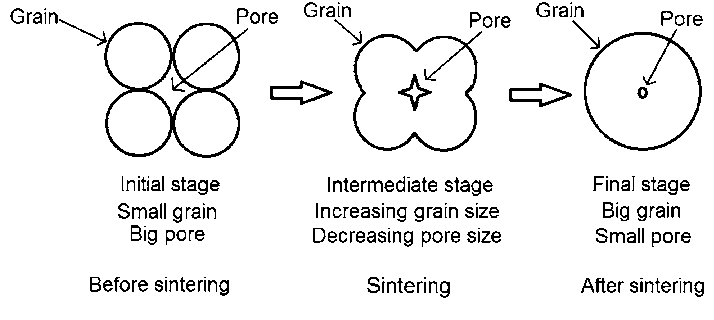

b) Sintering

: Sintering process uses heat or pressure to convert loose fine particles into a solid coherent mass without melting. After the sintering process, parts have a compact chemical structure and it enhances properties such as thermal conductivity, mechanical strength, electrical conductivity, whereas reducing porosity. Based on the technology, Selective Laser Sintering (SLS) 3D printers were developed. They use a high power laser to sinter parts.

If you would like to know a full list of the manufacturing processes and deep dive into them, the link below will be a beneficial starting point.

https://en.wikipedia.org/wiki/List_of_manufacturing_processes

List of manufacturing processes - Wikipedia

From Wikipedia, the free encyclopedia Jump to navigation Jump to search This tree lists various manufacturing processes arranged by similarity of function. Casting[edit] Data from Fundamentals of modern manufacturing[2] Labeling and painting[edit] Main art

en.wikipedia.org

'Technology > Manufacturing Engineering' 카테고리의 다른 글

| Process Capability Index: Cp, Cpk (0) | 2022.08.15 |

|---|---|

| Failure Mode and Effects Analysis (FMEA) (0) | 2022.03.22 |

| Lean Manufacturing (0) | 2022.01.13 |

| Six Types of Manufacturing Process (0) | 2022.01.08 |